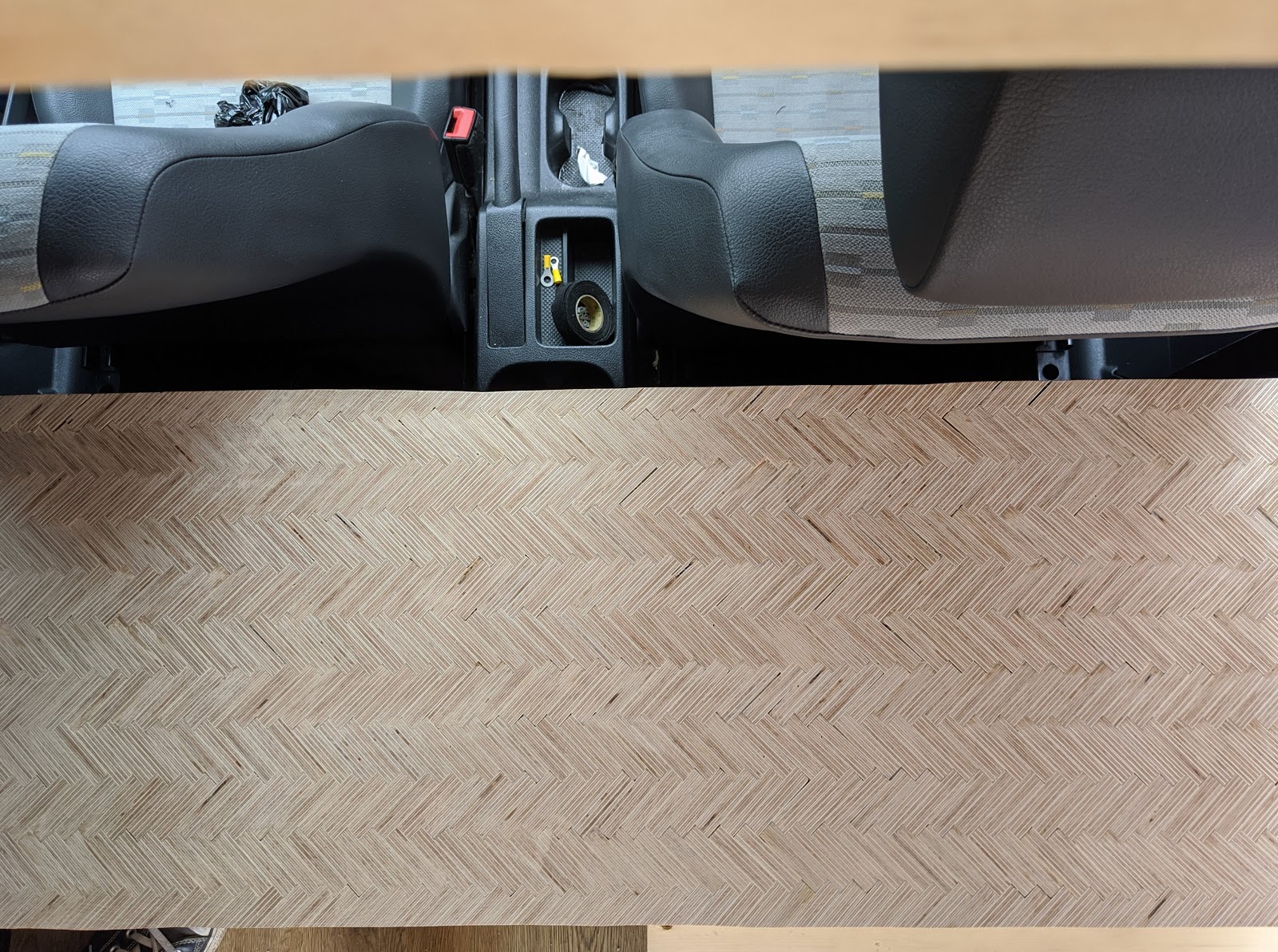

Because I like to make life difficult for myself, I decided rather than having a plain old boring worktop for my van, why not make a worktop our of 700+ different pieces.

The idea is pretty simple, however it is extremely time consuming.

This project took me around 15-20 hours of work from start to finish. It can probably be done a lot quicker if you have a better too set up.

Tools used;

- Mitre saw

- Circular saw

- Belt sander/circular sander

First off, I had to cut the 12mm plywood into strips. I chose 15mm strips - this would be the thickness of the worktop

Next, the strips of wood get cut into blocks. I cut mine at 5cm in length. I set up a stop on my mitre saw, so each block would be the same size.

Then, for the boring part, each block had to be hand sanded to get the burrs of wood off. I originally made 660 however this wasn't enough and I had to make 100+ more

|

|

Each block of wood was then glued together in a herringbone pattern on a flat surfaces on some grease proof paper, so that it doesn't stick itself to the floor.

Then once dry, I belt sanded it flat and level. Then trimmed the edges to shape.

Once all trimmed to shape, I sealed it with Osmo Top Oil Natural, which is really hard wearing stuff and heat resistant too

Easy peasy. It's not perfect, but it looks nice.